Technology

Possibilities

Imagine being able to shut down your medical gas system and within minutes being able to install a tie-in, a tee for future expansion or to cap off a line for renovation. Medical gas tie-ins can be installed as fast as you can drain the lines. Under extreme circumstances vacuum line tie-in's or emergency repairs can be completed on active lines.

Simply bleed the medical gas or vacuum line, clean and cut the pipe, mark the pipe and install a (ESP) fitting. It takes less than five minutes to install a permanent, leak-tight fitting. Since no brazing is necessary, no expensive nitrogen purge is required. Without brazing no copper oxides are created during installation. No additional time is needed to let the welded area cool to near room temperature. Gas lines go back into service as fast as appropriate verifications can be done by an Accredited Medical Gas Inspector.

MGI How It Works

The installation of (ESP) Medical Gas fittings takes minimal time and there is less patient disruption due to noise and brazing. The (ESP) installation is a cold braze alternative. There is no hot work, no burn permits, and no fire watches necessary. In addition, the speed of the (ESP) installation reduces system down-time and the additional costs associated with contract labor and overtime staffing. Fittings are cleaned for oxygen service in sizes 3/8" through 2". A simple hand held tool is all that is necessary.

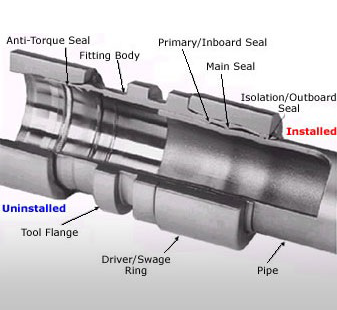

The leak-free seal, the result of (ESP) installation where the axial movement of the outer ring over the body swages the body onto the pipes surface. This compresses the pipe wall first elastically and then plastically. The pipe wall resists this swaging action, generating high unit loads at the contact points between narrow sealing lands inside the fitting body and the pipe surface. These contact stresses are sufficiently high to plastically yield the pipe surface under the sealing lands, forming a 360" circumferential, permanent, metal-to-metal seal between the pipe and fitting body. The driver, which experiences a small increase in diameter (elastic strain) during installation, exerts an elastic, radial preload on the metallic seals for the life of the connection.

.jpg)

.jpg)

Can MGI (ESP) Fittings be used underground?

The (ESP) connection is a perfect fit to underground work. There is no hot work so the piping does not anneal. This leaves the pipe more rigid to stand up to the underground environment.